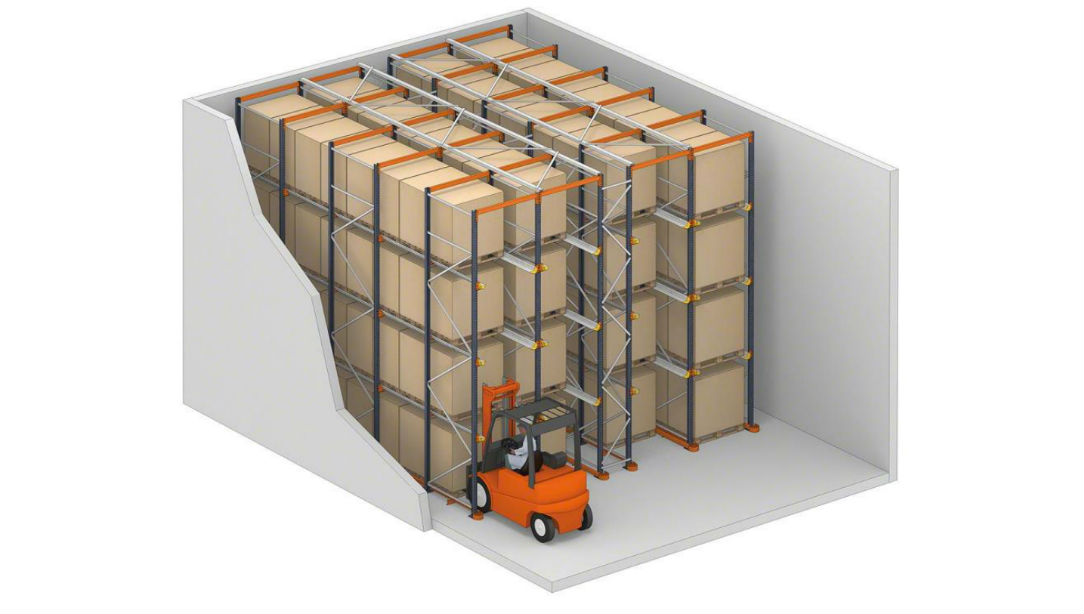

Drive-In Rack

Drive-in Pallet Racking provides maximum storage capacity using the minimum amount of space.

IDEAL IF...

- You need to store large quantities of the same palletized goods

- You want to store goods in batches

- You need a very high-density storage, more than Selective Pallet Racking

- You operate on the basis of First-In-Last-Out(FILO)

HOW IT WORKS

Drive-in Pallet Racking provides maximum storage capacity using the minimum amount of space. It is particularly suited to store a very large quantity of the same product. Loading and unloading are undertaken by means of counterbalance truck or reach-trucks that drives down each lane into the racks.

Two management systems are available: (1) Drive-In System, with only one access aisle, and the (2) Drive-Through System, with access to the load from both sides of the rack.

This racking system is most suitable for manufacturers of products that are produced in batch, or in warehouse operation where there are limited products SKU and pallets cannot be safely blocked or stacked. Frequently used in cold stores (refrigeration and freezing) which require maximum use of space for the storage of products in a controlled temperature.